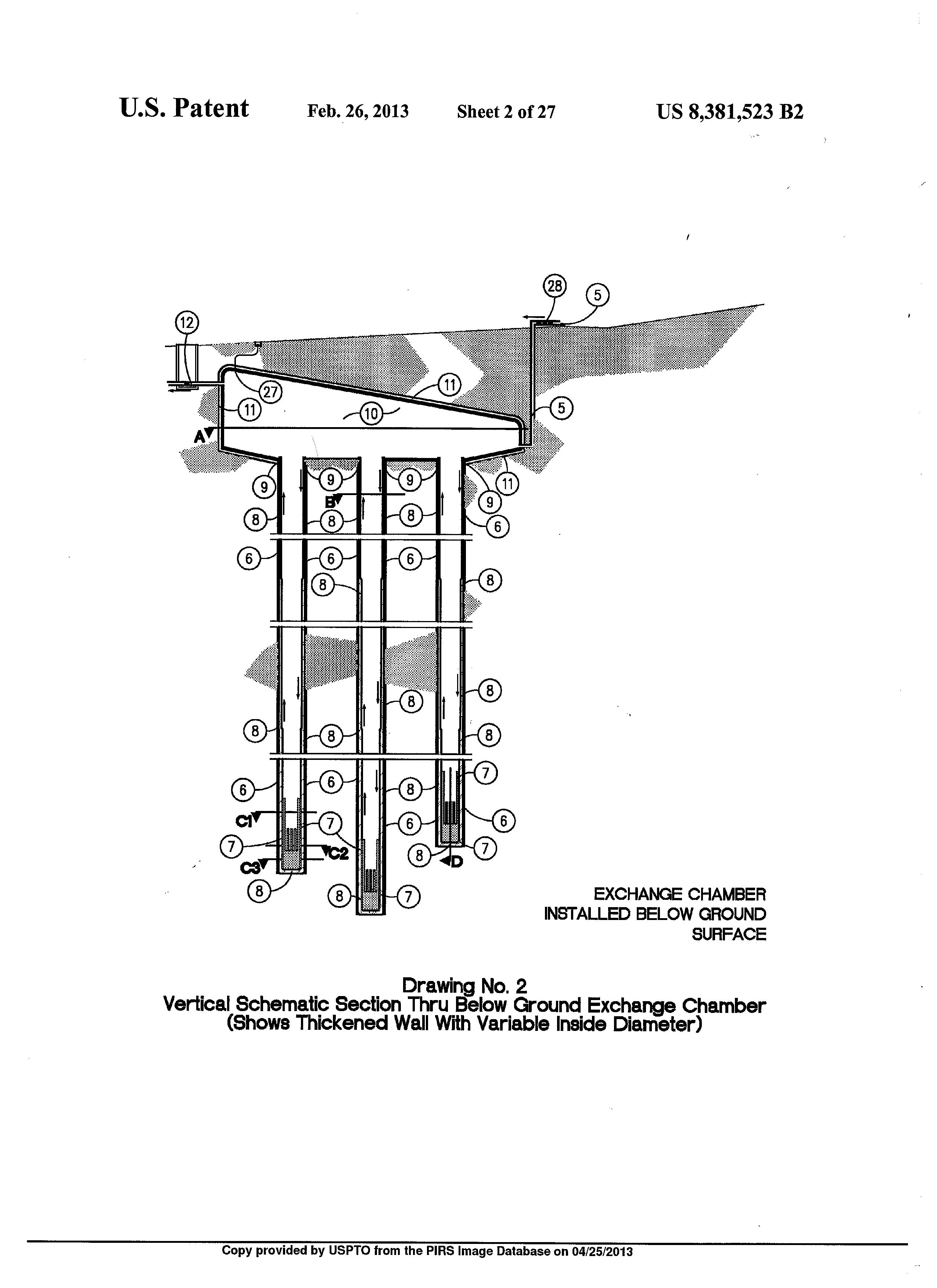

If we were to investigate geothermal energy applications, say for a university term paper or maybe just for fun; because that’s the sort of thing many of us would do with our Saturday morning, we might run across U.S. Patent 8,381,523 B2, which in turn could prompt the question, what is an Exchange Chamber? What does it do? Why does an Exchange Chamber, a simple enough sounding device, constitute serious, geothermal evolution, progressively carrying geothermal technology cost effectively into and beyond the 21st century? Below we see a crude conceptual sketch showing an Exchange Chamber with three heat cylinders visible in vertical-cross section. There are actually seven cylinders total capable of producing 2,000 MW. Incoming cool feed water can be seen on the lower right side of the Chamber; with heated fluid or steam (depending on system pressure) discharging on the upper left.

To clarify, let’s briefly digress for a moment, analogously considering development of today’s highly sophisticated combustion engine. Per Wikipedia’s[1], History of Steam Engines the first recorded steam engine, called the aeolipile was described by mathematician, Heron of Alexandria in 1st century A.D., more than 2,000 years ago. In other words, we know the concept of converting steam pressure into mechanical movement was known in Roman Egypt as early as the first century, though it wasn’t yet very useful. Experimentation continued for centuries until Thomas Newcomen, in 1712 designed the first commercially viable atmospheric engine, a reciprocating steam device utilizing cylinder and piston. This fundamental breakthrough was creatively employed in many ways until the 20th century, when it began to be replaced by more efficient steam turbines and finally, the internal combustion engine.

Regarding either steam or combustion engines, a single cylinder was a powerful thing, but the real breakthrough, the more significant value, was assembling several cylinders and pistons together within an engine casing. It’s the totality of the engine, combining the power of multiple cylinders and pistons, that finally gave birth to today’s ultra-smooth, incredibly reliable, amazingly powerful, wondrously useful machines. Circling back and completing our analogy, Z Group Energy’s Exchange Chamber is our geothermal engine combining the power of multiple, closed heat cylinders into a zero emissions system; a commercially viable geothermal technology. A single Exchange Chamber, for example can combine the power of say, ten heat cylinders, which at supercritical temperatures, yield a 3,000 MW power plant.

Side note: Yesterday’s conventional geothermal systems employ open, that is perforated wells both to harvest insitu geothermal brines via return wells; and to replenish below-ground reservoirs via injection wells. The Z Group Energy system on the other hand, employs closed heat cylinders, which can then heat clean water or some other fluid internally. No outside fluids or materials are taken into the ZGE system from outside the enclosed cylinders. Since no outside fluids are taken in and no internal fluids are injected below-ground, ZGE uses the term heat cylinder rather than the more familiar term, “well”.

Convective, non-partitioned flow allows Z Group Energy heating cylinders to be sealed, thereby eliminating the need for and use of insitu geothermal brines, which can contain corrosive or even toxic components. The enclosed heating system, using water as the heat carrier makes zero emissions possible, BUT as they say, “nothing’s ever so simple as it looks”. Every heat cylinder drilled will provide, as its discharge, heated fluid at a different temperature and pressure than any other cylinder. From an engineering standpoint, this variability makes combining these heat cylinders logistically complicated. It isn’t necessary here, to get into technical aspects of variable pressure, backflow, regulating valves, etc. other than to mention, if the discharges from multiple heat cylinders are to be combined; then the thermal energy, with variable discharge temperature and pressure captured and delivered by each individual cylinder must somehow be combined, mixed and homogenized to provide a safe, consistent, non-variable feed source enabling steam turbines to safely and reliably do their job.

ZGE accomplishes this via our patented Exchange Chamber, which revolutionizes storage of geothermal energy by standing the entire system on its head, so to speak. The Exchange Chamber enables storage of clean, unpolluted water to be conveniently held above-ground rather than from a below-ground reservoir harboring potentially corrosive or toxic brines.

The Exchange Chamber combines multiple, though variable thermal energy sources, that is, heat cylinders, then convectively mixes their discharges, transferring and balancing those variable heated discharges into a homogenous, dynamically stratified whole, where less dense, heated fluid or steam is extracted from the top of the chamber and cooler, more dense feed water is provided near the bottom. Multiple cylinders combined via an Exchange Chamber can drive a 3,000 MW power plant, meaning geothermal energy has entered a new era.

To reiterate, closed, non-partitioned heating cylinders make zero emissions possible by eliminating any contact with contaminated, below-ground geothermal brines. The Exchange Chamber then combines multiple heat cylinders, providing an economy of scale enabling zero emissions to be commercially viable and cost effective.

Comparatively speaking, conventional geothermal technology makes use of naturally occurring hot fluid storage below-ground. This fluid is harvested via open, perforated return wells and is used to drive steam turbines, in turn driving generators producing electricity. The below-ground reservoir must be replenished naturally or augmented via open, perforated injection wells as in-place fluids are removed from the reservoir. These in-place fluids are problematic to work with as they tend to be corrosive or even toxic, requiring expensive treatment. As a matter of convenience and differentiation, I refer to this technology as the conventional two-pipe, two-well system.

ZGE on the other hand, employs what can be called a closed, single-pipe system, whereby each heat cylinder is filled internally for heating, discharge, re-filling, re-heating, discharge, etc. in a continuous convective, non-partitioned, heat harvesting cycle eliminating any need for injection wells and eliminating contact with outside brines, contaminants, etc. Fracking is also eliminated. The Exchange Chamber, located at or near the ground surface enables combining multiple, closed heat cylinders, each conductively taking on thermal energy from below-ground hot rock, then convectively flowing significant quantities of heated fluid up into the Exchange Chamber where heated fluid is stored above-ground for clean, environmentally friendly, convenient access.

In other words, the Exchange Chamber tips the entire geothermal heat harvesting process upside-down, with storage conveniently above rather than below-ground. This permits ZGE’s system to utilize clean water or some other fluid, if appropriate, for energy transfer enabling a zero emissions technology, where the only by-product is water. It should be noted the Exchange Chamber can be installed above ground, bermed, partially buried or completely buried, but in any case, near the ground surface.

ZGE’s Exchange Chamber revolutionizes the way geothermal energy is stored. Storing electricity after it’s generated is difficult at best with the most common form being dammed hydroelectricity, actually storing water, not electricity. As you know, electricity is an energy flow traveling at the speed of light. It’s difficult to store flowing energy. If electrical energy isn’t used immediately, it’s usually wasted, which isn’t very cost effective. Power grid operators typically resolve this dilemma by running a mix of lower cost, base load plants near constant output, then ramp capacity up during demand peaks using higher cost, peaker plants.

ZGE doesn’t propose to expensively store electricity after it’s produced either. Instead ZGE proposes cost effectively storing clean hot water so electricity can be generated at any time, on demand. This hot water storage ability diminishes, maybe eliminates the need to store electricity, given adequately predictive control systems capable of anticipating demand peaks and valleys – the good news being, this technology already exists and is used for effective grid management.

Anyway, if you’ve been searching clean energy technologies on Saturday morning or some other time, I hope we’ve shed some light on some of the ways our Exchange Chamber constitutes an exciting new geothermal innovation.

If you’d like to know more about ZGE’s revolutionary Exchange Chamber, please email me at: [email protected], or just leave a comment on any page of our website, Facebook Page or YouTube Channel. Thank you for your interest in innovative geothermal energy.

[1] “History of the Steam Engine,” Wikipedia, July 16, 2017, https://en.wikipedia.org/w/index.php?title=History_of_the_steam_engine&oldid=790790566.