Supercritical Deep Ocean Vent

Z Group Energy (ZGE), head quartered in Coolidge, Arizona is an alternative, clean energy partnership engaged in system development and design for manufacture of supercritical water to be used for electricity generation. Our patented method can produce electricity for approximately $0.008/kWh with its only emission being clean water.

We filed U.S. Patent application #12/473,237 on May 27, 2009 with publication following December 2, 2010. Our application came under review two years or so after publication and on February 26, 2013 we were issued U.S. Patent #8,381,523 B2, entitled: GEOTHERMAL ELECTRICITY PRODUCTION METHODS AND GEOTHERMAL ENERGY COLLECTION SYSTEMS.

Our ZGE system is only geothermal in the sense we mine heat from below earth’s surface, but similarity ends there. Our closed heat-exchange wells utilize thermal energy from hot dry rock (HDR) to heat internally circulated clean water, transferring heated water from multiple wells to our patented Exchange Chamber for pressure controlled use. Therefore, our innovative technology does not utilize brines from geothermal reservoirs, is not porosity/permeability/fracking dependent and eliminates handling corrosive and/or toxic geothermal brines altogether. No injection wells are needed.

Our patented, non-partitioned convective flow, thermal energy harvesting system manufactures supercritical fluids, converting them to steam for use in electricity production at costs competitive with any other electricity producing technology. Using H2O as the fluid, our patented system yields zero polluting emissions. To reiterate: supercritical temperatures are obtained geothermally using hot, dry rock. Our system does not use below-ground water or fluids so NO FRACKING is required. The high costs associated with enhanced geothermal system (EGS) development are eliminated with our sealed system. Testing of the IDDP-1 well by Iceland’s Deep Vision consortium suggest one of our sealed wells is capable of producing 36MWe under sub-supercritical conditions and as much as 40-50 MWe per well under supercritical conditions.

ZGE has since learned by example from helpful Japanese Snow Monkeys living high atop their snow-capped mountains, how environmentally friendly, clean and relaxing Geothermal really is. Now it’s for us to teach our Snow Monkey friends how to supercritically, Eco-effectively keep the reading lamp lit.

*****

Why is our Z Group Energy supercritical system innovative or significant?

The short answer is: $0.008 USD per kWh. This is energy industry competitive and ZGE’s only emission is clean water.

The long answer is: NON-PARTITIONED CONVECTIVE FLOW SUPERCRITICAL SYSTEM.

The longer answer is: ZGE tips the old geothermal reservoir upside down, storing clean water (or some other non-hazardous fluid) conveniently above- ground (or near ground surface), beyond reach of potentially corrosive or toxic insitu geothermal brines; whereas conventional geothermal technologies tap directly into those potentially problematic below-ground brines, requiring treatment. This doesn’t allow ZGE to store electricity directly, but does enable cost effective, above-ground storage of supercritically heated water for on-demand electricity production at any time. ZGE harvests heat, not fluid – a ground-breaking (pun intended) breakthrough in electricity generating technology.

The longest answer is multi-faceted, but a few primary reasons are as follows:

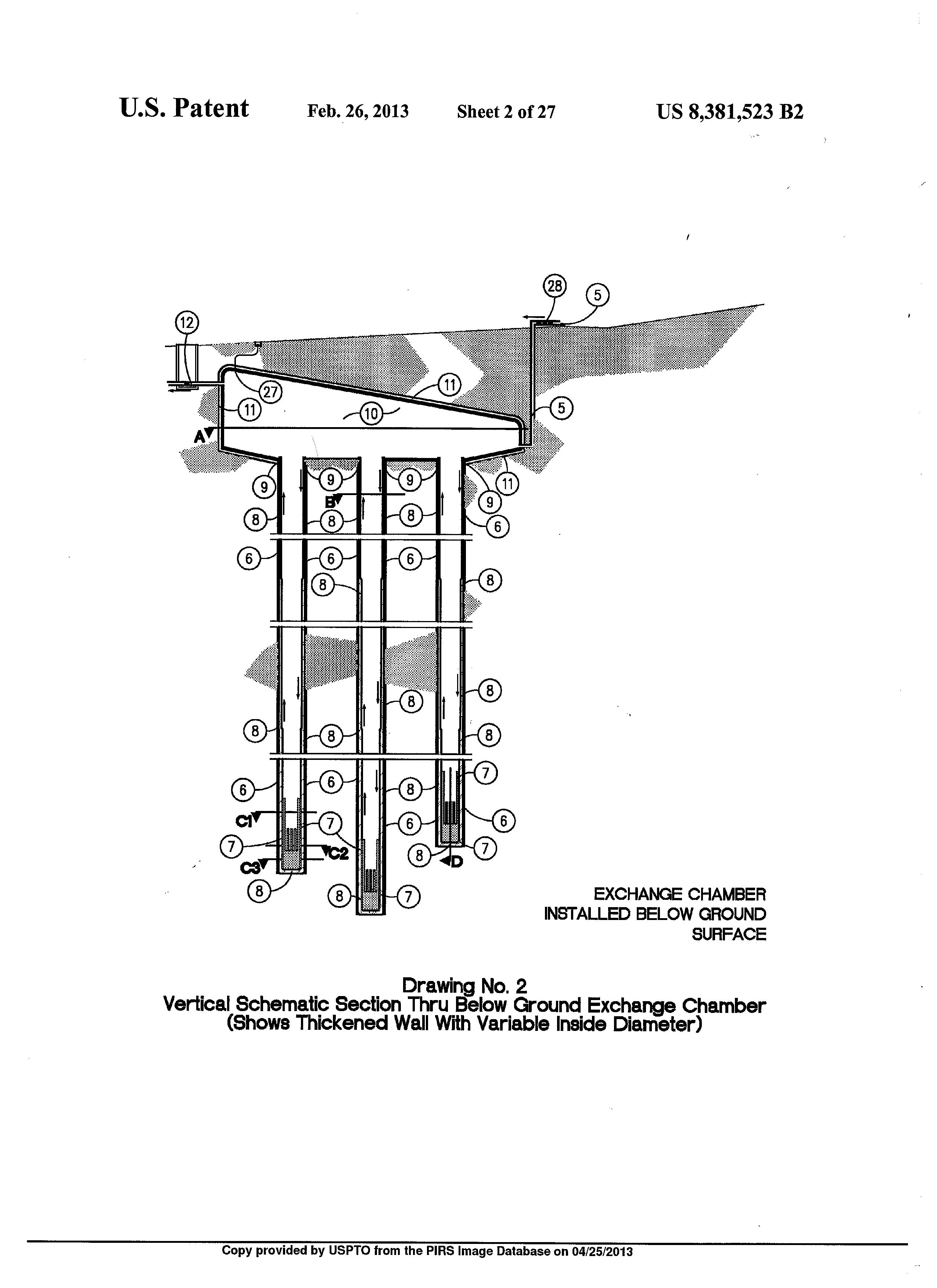

Our unique, non-partitioned flow, convective Heat Cylinders (wells) are closed, not perforated. Clean, cool, relatively more dense water is introduced to the tops of the cylinders near the bottom of the Exchange Chamber, sinks down and as it sinks to sufficient depth, is heated to supercritical temperatures, reducing density until rising and collected in the Exchange Chamber. There can be any number of heat cylinders connected together via an Exchange Chamber or Exchange Chambers, which are large diameter, specialized containers able to safely withstand high temperature and pressure.

(Photo from Photo Bucket)

An Exchange Chamber fed by a Pressurized (or non-pressurized, depending on system design) Mixing Container, feeds any number of heat cylinders with feed water (from near the bottom of the chamber); collects heated, supercritical fluid from multiple cylinders; convectively mixes and homogenizes fluid temperatures and pressures received from multiple heat cylinders; then discharges mixed, heated fluid or steam (from near the top of the chamber) to a Pressurized Storage Container for final temperature and pressure adjustment ahead of the phase separator(s) and turbine(s). Under supercritical conditions the heated fluid will be neither liquid or steam, holding enormous amounts of energy conservatively yielding as much as ten times the output of a conventional geothermal power plant, i.e., 36 MW per supercritical well compared to 3-5 MW per well for conventional systems.

The term supercritical conditions is particularly noteworthy because several years ago when we developed our cutting-edge, sealed, non-partitioned convective flow geothermal technology and our patent was filed and under review, we understood how cost effective our non-partitioned system technology would become if below-ground temperatures above 374°C could be reached and stored for thermal energy transfer and conversion to electric energy. This vision was hindered at that time by drilling equipment metallurgy experiencing difficulty at temperatures exceeding 300°C or so. Today, the metallurgy picture has upgraded drastically.

Testing carried on in Iceland over the past decade has generated useful drilling and flow data pertinent to our non-partitioned heating cylinder technology. Significant advances in geothermal energy have been made by the international consortium, Deep Vision working together in Iceland since year 2000. Iceland’s IDDP-1 geothermal well, originally planned to be ±4,000m deep, while being drilled in 2009, encountered a magma intrusion with temperatures in the range of 900°C to 1,000°C. This magma intrusion effectively collapsed and closed the bore hole at the 2,104 m depth. The IDDP-1 well was thankfully salvaged, and a sacrificial (permanent) casing was installed to a production depth of 2,069 m. Water was put down the bore hole and over time, the well stabilized. Subsequent testing over a two-year period, yielded wellhead temperatures of approximately 450 °C at a pressure of 140 bars and enthalpy of 3,150 kJ/kg. Though impressive, these are not supercritical results.

More significantly, using appropriate pressure controls, Deep Vision consortium members measured well output from IDDP-1 as high as 36 MWe. The consortium further determined reaching and maintaining wellhead pressures above 450 °C with supercritical flow-rates of 0.67 cubic-meters/second (24 CFS) would be sufficient to produce high temperature steam generating as much as 40-50 MWe. This is a supercritical estimate substantiating ZGE’s patented technology in real time.

Additionally, advancements in deep-drilling technology since that time (2007-2016) have enabled the 2nd phase of Iceland’s Deep Drilling Project, IDDP-2, in January of 2017, to reach a depth of 4,659 meters, at 427°C and 340 bars. Supercritical Icelandic reality proves in real time, not in tomorrow’s future, that Z Group Energy’s expectation for a non-partitioned heating cylinder geothermal system maintaining large, commercially viable quantities of supercritical fluid at storage temperatures maintained in a range above 425ºC, 221 bars, or above are now possible. This reality, in turn suggests as this supercritical expectation comes to fruition, the Z Group Energy non-partitioned, supercritical system is one of the most cost effective, least emission producing methods for producing electricity now available.

Interestingly when pressures exceed the supercritical value of 22.064 MPa (220 bars), the specific heat of water drops significantly, with the largest drop occurring from 22.5 MPa to 23.0 MPa, wherein specific heat falls from 690.6 kJ/kg°C to 284.3 kJ/kg°C. At 30 MPa the specific heat of water drops to 27.03 kJ/kg°C. In other words, increasing pressure above supercritical engenders diminishing returns, placing a financially and technologically convenient cap on system pressure.

It should be noted that supercritical energy investigated by Iceland’s IDDP-1 and IDDP-2 Projects are further supported by Italy’s Descramble Project and Japan’s Beyond-Brittle Project. ZGE’s closed, non-partitioned convective flow cylinders and Exchange Chamber technology can cost-effectively provide significant efficiency improvements for all three of these projects.

Our enclosed, non-partitioned, convective flow regime utilizing any number of individual heating cylinders (wells) for feeding (injecting), heating and harvesting (returning) supercritical heat within each cylinder, sans separate injection/return wells, is revolutionary. More importantly for commercial purposes, any number of these sealed Heat Cylinders can be bundled together via an Exchange Chamber. It is also possible to utilize multiple Exchange Chambers should production demand it. This design flexibility aspect makes it possible to size Exchange Chamber(s) at the optimum structural, cost-benefit point maximizing safe, reliable production, while minimizing thermal energy losses. Our 100% innovative Exchange Chamber makes it possible to connect any multiple number of Heat Cylinders together, combining and convectively mixing their variable discharges to a homogenized, dynamically stratified whole; maximizing heated, supercritical fluid storage and production while minimizing potential equipment damaging, temperature/pressure variation feed hiccups.

Our Exchange Chamber makes it possible to safely and cost effectively exceed previously possible geothermal electricity generation capacities via dynamically stratified, convectively mixed, supercritical, thermal storage within the Exchange Chamber and Non-Partitioned Heating Cylinders. ZGE literally manufactures clean supercritical fluid for electricity production – not by harvesting corrosive geothermal brines from a difficult to control open-geological system, but by simply mining heat, dry or wet, though preferably dry, from our closed, pressured controlled system.

Conventional geothermal technology uses below-ground, insitu liquid reservoirs and brines. The Z Group Energy system tips this upside down (we called it the mushroom initially) by using below-ground hot dry rock and our Sealed Non-Partitioned Convection Cylinders as the conventional conductive heat source with heat transference by unpartitioned convection, but using our above-ground Exchange Chamber as the reservoir. This allows the use of uncontaminated, pure, clean or purified water (or some other non-hazardous fluid) for supercritical heat storage and convective thermal energy transfer, thereby eliminating any need for using potentially toxic, corrosive, equipment damaging, geothermal brines directly. No fracking is ever required with the ZGE system.

Because ZGE Exchange Chambers store pressure controlled, supercritical fluid in close proximity to steam turbines and generators – our system enables clean reliable electricity generation 24/7/365.

Our cost effective, zero emissions Z Group Energy technology renders the dream of every electric car, truck and train manufacturer an economically viable reality. It revolutionizes the infinite possibilities of our electricity dependent – residential, commercial and industrial 21st century lives. Low cost, clean electricity production via the Z Group Energy closed, supercritical, system brings every residential dream; every industrial dream; every transportation dream; every medical dream and every food processing dream across the globe into cost effective, non-polluting, economic reality… and this is why our closed, Z Group Energy, supercritical system is innovative and significant.

Why would we as a shared civilization not reserve, conserve and utilize our precious fossil and nuclear fuels for targeted purposes singularly benefited by such fuels and materials, while simultaneously utilizing a zero-polluting, cost effective electricity production method like ZGE’s supercritical geothermal technology for electrical power applications?

Save